Anchor Cages

Preferred supplier of Vestas, SGRE, Enercon and Nordex

Production capacity >2000 anchor cages per year

3 Manufacturing sites in Europe & India, a Logistic Centre in Northern Europe

Complete Anchor Cages

FOR THE FOUNDATION OF WIND TOWERS

At Barranquesa we supply complete anchor cages, which include the flanges produced internally in our company, as well as other components purchased directly from our trusted partner companies.

The anchor cage is an essential component that must be delivered before construction work begins on the wind turbine foundations. In this regard, Barranquesa has proven experience with all global OEMs in the market, allowing us to avoid technical problems during the assembly phase.

To guarantee punctuality in deliveries, Barranquesa offers the market three manufacturing plants in Spain and India dedicated to this product, in addition to a Logistics Centre in Northern Europe. We have more than 15,000 m2 of storage space available to our customers, allowing us to deal with any unforeseen event that may arise in the development of the project.

This allows us to provide service to our customers in any part of the world where their projects require it. In addition, we manage all the logistics to deliver the anchor cages in the shortest possible time, whether pre-assembled or not.

Our rigorous production process allows us to supply anchor cages with the highest quality and reliability.

This is the process

1.

2.

Manufacturing of flanges in-site and procurement of components

3.

Possibility to Pre-Assemble and store the anchor cage in our facilities

4.

Deliver the complete Anchor Cage Solution around the world

Products

1. FOUNDATION FLANGES

We can manufacture full flanges (360°) or segmented flanges. We have the knowledge and staff to advise on the best option.

2. MOUNTING KITS

We supply all the necessary components for the assembly of wind turbine foundations: anchors and auxiliary parts.

Services

With the objective of reducing the Levelized Cost of Energy (LCoE) for the project, we are equipped to provide comprehensive design and optimization services for wind tower foundations.

Objective: reduction of the LCoE of the project

We offer the possibility to deliver the anchor cages pre-assembled, which significantly saves time during the assembly process at the wind farm. By providing this service, we streamline the installation procedure, reduce on-site labor requirements, and minimize potential delays, thereby enhancing the overall efficiency and cost-effectiveness of the project.

We have more than 10,000 m2 available to store the finished product. This capacity allows us to offer a value-added service: in the event that project construction times do not meet forecasts, we guarantee the safety and security of the goods, offering ad-hoc deliveries to adapt to our customers’ times and needs.

Material purchase

Direct relationship with steel mills

Cutting sectors

MAG Welding

International Welding Engineer in house. Qualified process according to EN 15614-1. Welders qualified according EN 9606-1

Machining

CNC turning machines

Machining in 360° rings or segmented

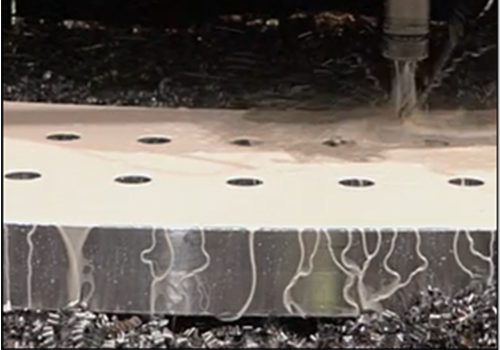

Drilling

CNC Drilling-milling machines

Drilling in 360° ring or segmented

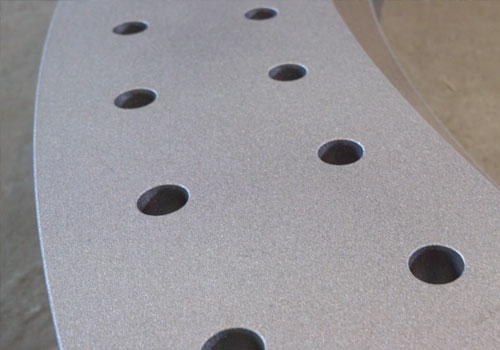

Surface treatment

Sand blasting, painting, metallizing and others

Anchor bolts

Trustworthy and Approved Suppliers

Picking

Worldwide Logistics

Full management of the logistics and packaging for deliveries to any part of the world

Assembling services

We deliver pre-assembled anchor cages by specialized personnel and ensuring quality standards

Satisfied customers