MANUFACTURING PROCESS:

Anchor cages

We are able to fulfill all your requirements and needs with the help of our outstanding production process:

Material Purchase

Material Purchase

Independent source directly from the mill

Cutting sectors

Cutting sectors

Traditional cutting method using oxy-fuel torches to cut through steel up to 240 mm thickness or plasma cutting for smaller thicknesses

MAG welding

MAG welding

International Welding Engineer in house. Qualified process according to EN 15614-1. Welders qualified according EN 9606-1

Machining

Machining

CNC turning machines

Machining in 360º rings or segmented

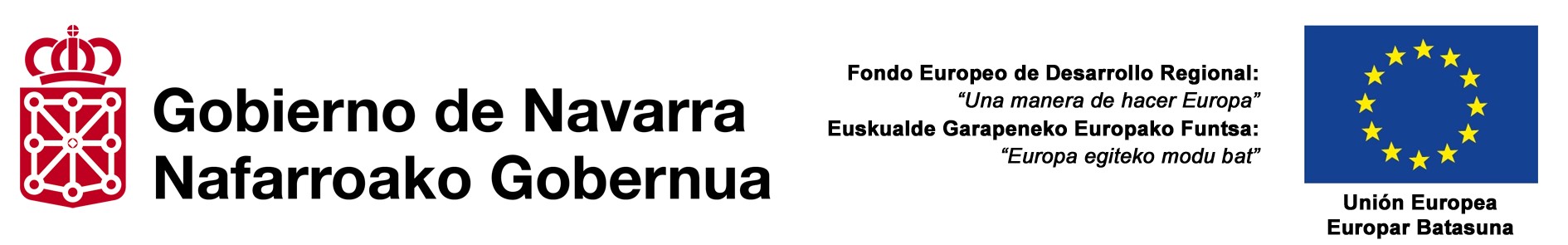

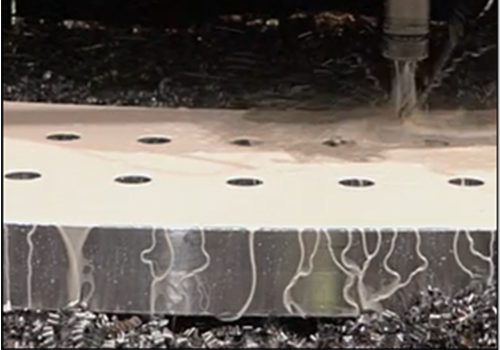

Drilling

Drilling

CNC Drilling-milling machines

Drilling in 360º ring or segmented

Surface treatment

Surface treatment

Sand blasting, painting, metallizing and others

Anchor bolts

Anchor bolts

Trustworthy and Approved Suppliers

Picking

Picking

Preparation of the KITS ready to package: flanges, bolts and small pieces

Several specific references procured from different suppliers

Assembling services

Assembling services

We deliver pre-assembled anchor cages by specialized personnel and ensuring quality standards

Worldwide Logistics

Worldwide Logistics

Full management of the logistics and packaging for deliveries to any part of the world